The best Precision Mechanical Workshop to turn your ideas into Projects!

The Best Precision Mechanical Workshop

To turn your ideas into Projects!

Welcome to the world of precision machine shops, where excellence merges with project transformation!

If you are looking for a reliable partner to pursue your most ambitious ideas, you are in the right place.

Our machine shop is renowned for quality and precision work, offering customized solutions to meet the needs of engineers, architects.

With a wide range of state-of-the-art machinery and a team of highly skilled experts, we are able to work on projects ofall sizes and complexities.

Our expertise ranges from the design and manufacture of precision mechanical components.

We know how important it is for you to get superior results and meet deadlines, which is why we are committed to providing you with efficient and excellent services.

Discover the difference a high-level precision machine shop can make to your projects.

Contact us today for a consultation and find out how we can turn your ideas into reality!

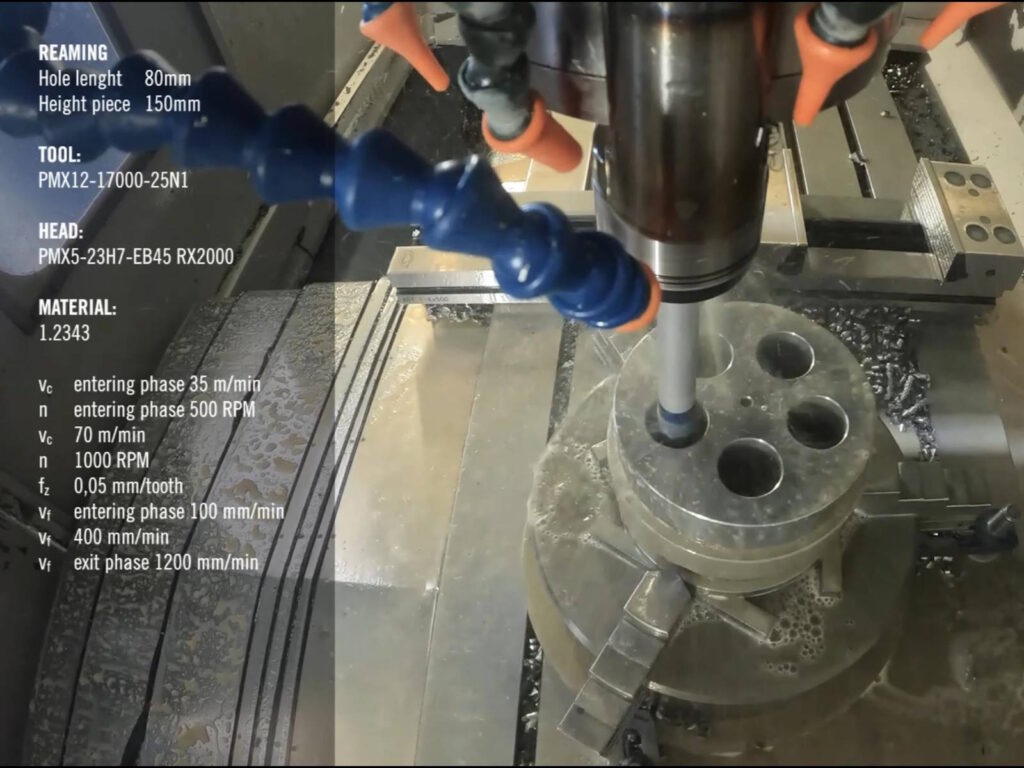

Some of our mechanical Processing

Rettifica turcite su pattini

Rettifica turcite su pattini

6 dicembre 2024

programma "Pole position" che ci vede protagonisti

Fresatura Albero grandi dimensioni

Fresatura Albero grandi dimensioni

La passione per il nostro lavoro

Precision machine shops play a key role in the implementation of successful projects in various industries.

These workshops are distinguished by their ability to work with extreme precision and quality, providing customized solutions that meet the specific needs of engineers, architects and designers.

Precision mechanical work consists of the design, manufacture, and assembly of mechanical components with very tight tolerances .

This type of work requires the use of highly sophisticated machinery and state-of-the-art technology to ensure the required precision.

Working with a precision machine shop offers many advantages for designers and engineers.

One of the main advantages is the possibility of obtaining high-quality mechanical components made to very tight tolerances that ensure superior performance.

In addition, precision machine shops are able to work on projects of any size and complexity, offering customized solutions that meet customers’ specific needs.

Precision machine shops are widely used in various industries, including aerospace, automotive, electronics, medical, and many others.

In these industries, the precision and quality of mechanical components are critical to ensure the safe and efficient operation of end products.

Numerous projects have been successfully implemented, often complex and of high quality.

Every project requires a very high level of precision and quality, which only the best precision machine shops can guarantee.

Precision machining

Turning

Turning machining with modern machines for metals, including steel, aluminum, cast iron, bronze, brass, and copper. We can also turn plastic, Teflon and other plastics.

Milling

Contract machining of high-precision CNC milling using state-of-the-art machinery for both small, medium and large quantities. Production of components from drawings and according to customer specifications, including using CAD/CAM technology

Grinding

Indispensable process to give the product the highest degree of precision and finish. The Celotti Roberto Mechanical Workshop performs cylindrical grinding, gear machining, carpentry, metal work and more.

Medium Heavy

Medium-heavy machining requires specific machinery and heavy-duty cutting tools for machining large, heavyweight parts. Precision and quality of materials are essential to ensure the robustness and efficiency of finished products.

Prototyping

Process of creating and testing prototypes for mechanical systems or components. This is a design, development, and production stage that uses CAD software, precision machines, and specialized equipment to create high-quality prototypes quickly and efficiently.

Specials

High-quality customized solutions for industries such as aerospace, defense, automotive, energy, and medical. We provide full service from design to production, assembly and final testing. We collaborate with clients to develop innovative solutions.

Call us

Monday through Friday

Hours: 8 - 12 / 14 - 18

Write to us

We make any detail

The contract mechanical parts making service consists of producing mechanical parts to specific customer requirements.This service is useful for companies that do not have the resources or expertise to produce mechanical parts in-house.

The process of making mechanical parts may include drawing, prototyping, production, and delivery. The advantages of this service include the possibility of having custom-made mechanical parts produced with the latest technology and with maximum efficiency.

In addition, the service of contract manufacturing of mechanical parts can be cost-effective, as it eliminates the cost of purchasing expensive equipment and machinery.

We work closely with our specialized partners to offer our customers a wide range of processing and meet their every specific need.

Our goal is always to ensure the complete satisfaction of all our customers.

Quick delivery is an important plus we offer to all our customers.

Reliable and fast shipping to Italy, Europe and all over the world with the best international couriers.

We are ISO 9001 certified, demonstrating our commitment to quality, continuous improvement and customer satisfaction.

A unique service for making your manufactured mechanical part efficiently and economically.

21 maggio 2025